#073: Your Biggest Problems Aren't Really "Problems"

- Por

- Episodio

- 73

- Publicado

- 8 mar 2018

- Editorial

- 0 Calificaciones

- 0

- Episodio

- 73 of 421

- Duración

- 27min

- Idioma

- Inglés

- Formato

- Categoría

- Economía y negocios

Symptoms vs. problems. How to identify the underlying problems causing low productivity, and solve them for good. How do the big successful contractors do it? Episode #73 of The Construction Leading Edge podcast from www.constructionleadingedge.com will show you a process you can use to get at the underlying problems to the symptoms you're dealing with, and solve them. Here's the process outlined in this construction podcast: 1. Identify the symptom or issue you're dealing with. 2. Ask, "What could be causing that symptom or issue?" Make a list of Level 1 potential causes. 3. For each of those causes/issues, list the underlying problems that could be behind them (Level 2, Level 3, etc.) 4. Keep asking, "What could be causing that?" until you get to the basic underlying problem. 5. Design a system, process or plan that will solve the basic underlying problem. Let's look at the example of Low Crew Productivity: Level 1 Potential Cause: Lack of Material Level 2 Causes behind the lack of material: 1. Material wasn't ordered on time. 2. Material was damaged during double handling. 3. Material was delivered to the wrong place. 4. Somebody forgot to pick up material from shop or supply house. 5. Material was lost. Solutions to the Level 2 Causes behind the lack of material: 1. Develop a material procurement schedule to ensure material is ordered and delivered at the right time. 2. Have a jobsite logistics plan to pre-plan where material will be offloaded so it doesn't have to be moved. 3. See #2. 4. Have a daily planning process. Stock commonly used materials at the jobsite or shop. Hire a runner to pick up materials. 5. Establish one person and one place where all deliveries go to avoid deliveries being lost. Level 1 Potential Cause: Crew efficiency and production Level 2 Causes behind low crew efficiency and production: 1. Cell phone usage. 2. Too much time in meetings. 3. Spending time picking up materials. 4. Time spent fueling trucks and equipment. 5. Gathering tools and supplies at the shop in the morning. 6. Time lost driving to and from lunch. 7. Lack of goals. They don't know what winning looks like. 8. Lack of planning. 9. Insufficient tools or poor tools. 10. Work area is not ready when they get there. 11. Work may be getting done but it's not reported to the office. 12. Crew waits for instructions from the boss. Solutions to the Level 2 Causes behind low crew efficiency and production: Listen to the podcast to hear about the systems, processes and solutions you can use. Resources mentioned in this construction podcast: Secrets Strategies of Successful Contractors: Free Videos for Construction Business Owners Schedule your free Business Breakthrough Coaching Call

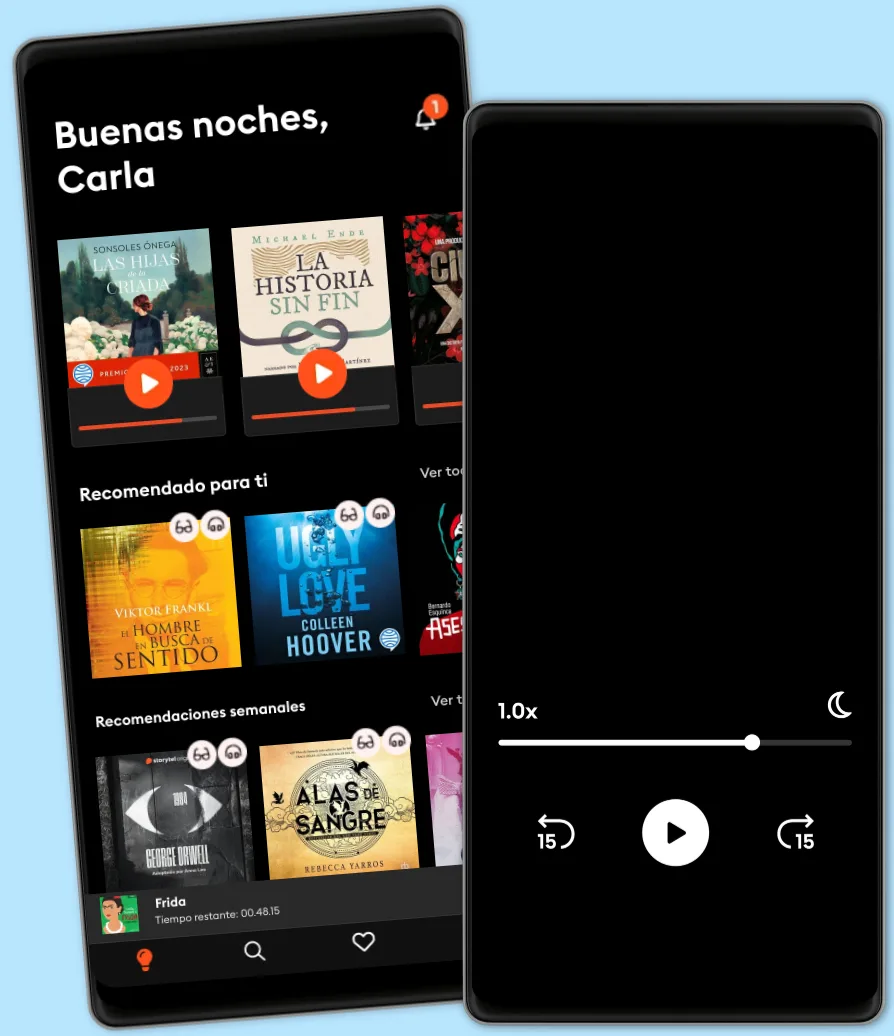

Escucha y lee

Descubre un mundo infinito de historias

- Lee y escucha todo lo que quieras

- Más de 1 millón de títulos

- Títulos exclusivos + Storytel Originals

- Precio regular: CLP 7,990 al mes

- Cancela cuando quieras

Otros podcasts que te pueden gustar...

- Business WarsWondery

- The Journal.The Wall Street Journal & Spotify Studios

- Lutz & Jasper powered by Cherry VenturesCherry Ventures

- Chiedi chi era GardiniPiano P

- The Punekar PodcastIdeabrew Studios

- The Can Do WayTheCanDoWay

- HW News Editorial with Sujit NairHW News Network

- HW News Business Tit-BitsHW News Network

- HW News Business HeadlinesHW News Network

- DREAMERS, DISRUPTORSThe Quint and Bloomberg Quint

- Business WarsWondery

- The Journal.The Wall Street Journal & Spotify Studios

- Lutz & Jasper powered by Cherry VenturesCherry Ventures

- Chiedi chi era GardiniPiano P

- The Punekar PodcastIdeabrew Studios

- The Can Do WayTheCanDoWay

- HW News Editorial with Sujit NairHW News Network

- HW News Business Tit-BitsHW News Network

- HW News Business HeadlinesHW News Network

- DREAMERS, DISRUPTORSThe Quint and Bloomberg Quint

Español

Chile