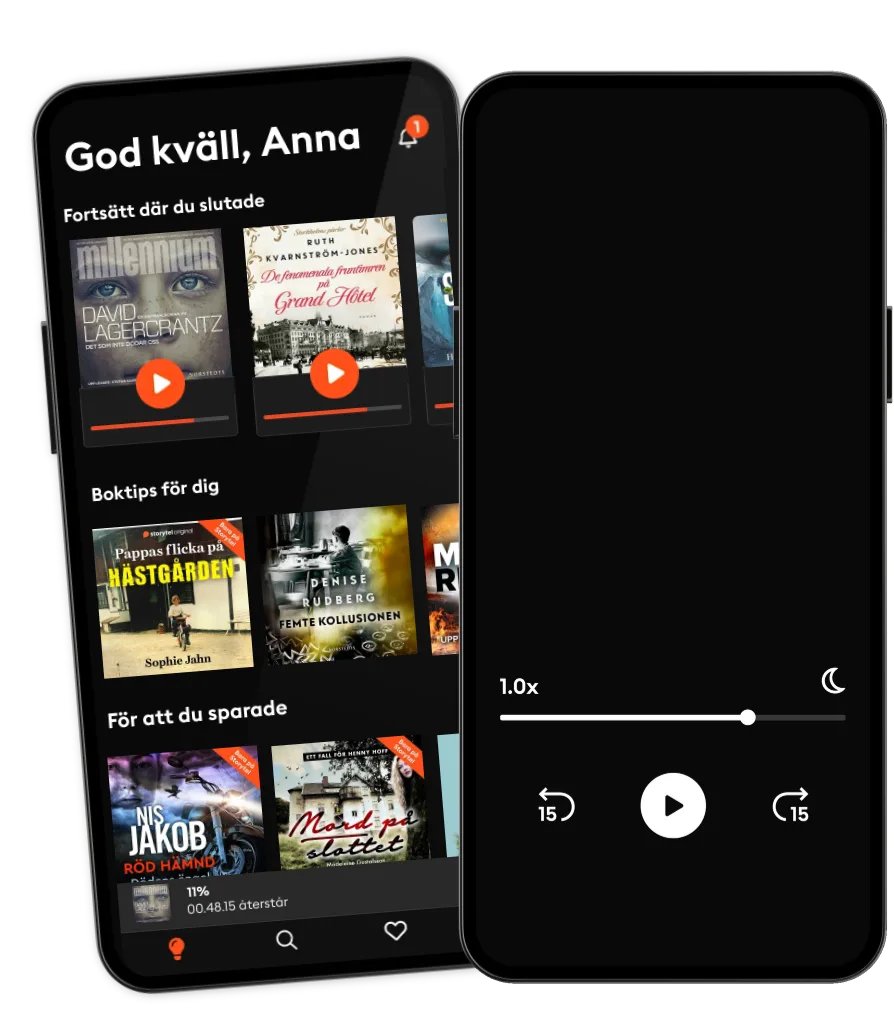

Lyssna när som helst, var som helst

Kliv in i en oändlig värld av stories

- 1 miljon stories

- Hundratals nya stories varje vecka

- Få tillgång till exklusivt innehåll

- Avsluta när du vill

SONY: HOW THE JAPANESE KAIZEN MENTALITY HELPED THE BRAND OVERCOME CRISES

- Av

- Förlag

Introduction to Kaizen Philosophy and its Relevance in the Japanese Context The word "kaizen" is a combination of two Japanese characters: "kai" (change) and "zen" (for the better). Literally translated, it means "continuous improvement." However, kaizen transcends the literal meaning and becomes a philosophy of life, especially in the Japanese corporate environment. Sony, one of the largest technology companies in the world, has adopted this mentality since its inception and has used it as one of the pillars to overcome crises throughout its history. In the post-World War II period, Japan faced enormous economic and social challenges. Rebuilding the country required not only government efforts but also a change in business mindset. It was in this context that the concept of kaizen began to gain traction, driven by figures such as Toyota's Taiichi Ohno and W. Edwards Deming, an American consultant who profoundly influenced Japanese management practices. Kaizen is not just about big innovations or radical changes. It is about small, everyday improvements that, over time, add up to significant transformations. At Sony, this approach was applied at all levels of the organization, from the production line to senior management. Sony founder Masaru Ibuka believed that innovation and quality were direct results of a culture of continuous improvement. Fundamental Principles of Kaizen Focus on People: Kaizen values teamwork and the participation of all employees, regardless of their hierarchical level. Incremental Improvements: Rather than seeking drastic changes, kaizen encourages small, daily adjustments. Eliminating Waste: Identifying and eliminating inefficient processes is essential to optimizing resources. Respect for the Work Environment: A healthy and respectful environment motivates employees to contribute ideas. Results Orientation: Every action must be evaluated based on its concrete impacts. Practical Example Imagine that you are a line manager for a television production line at Sony. In applying kaizen, you decide to implement daily five-minute meetings with your team to discuss problems and suggestions. During one of these meetings, an employee suggests adjusting the position of a machine to reduce the time spent handling components. This small change saves five seconds per unit produced. With a daily production of 1,000 units, this results in savings of over an hour per day. This example illustrates how small improvements can have a significant impact.

© 2025 Max Editorial (E-bok): 9781779749154

Utgivningsdatum

E-bok: 15 april 2025

Taggar

- Följeslagaren Sofie Sarenbrant

4

- Skugga över Slagtjärn Rolf Börjlind

4.1

- Tornet Dag Öhrlund

3.8

- Konstnären Dag Öhrlund

4.1

- Nattankare Kristina Ohlsson

4.1

- När stjärnorna faller Mari Jungstedt

4

- Välkomna till vårt äktenskap Julia Dufvenius

4

- Skottskador Mikael Ressem

4.1

- Ingen väg ut Lee Child

3.6

- Vår sjätte attaché Denise Rudberg

4.3

- En dold skönhet Lucinda Riley

4.3

- Alfa Lina Areklew

3.9

- Vägen in Peter Lindmark

4.4

- Del 1 - Flykten till Chicago Veronica Almer

3.8

- Stål-Berit Martina Haag

3.2

Därför kommer du älska Storytel:

1 miljon stories

Lyssna och läs offline

Exklusiva nyheter varje vecka

Kids Mode (barnsäker miljö)

Premium

Lyssna och läs ofta.

169 kr /månad

Exklusivt innehåll varje vecka

Avsluta när du vill

Obegränsad lyssning på podcasts

Unlimited

Lyssna och läs obegränsat.

229 kr /månad

Exklusivt innehåll varje vecka

Avsluta när du vill

Obegränsad lyssning på podcasts

Family

Dela stories med hela familjen.

Från 239 kr /månad

Exklusivt innehåll varje vecka

Avsluta när du vill

Obegränsad lyssning på podcasts

239 kr /månad

Flex

Lyssna och läs ibland – spara dina olyssnade timmar.

99 kr /månad

Spara upp till 100 olyssnade timmar

Exklusivt innehåll varje vecka

Avsluta när du vill

Obegränsad lyssning på podcasts

Svenska

Sverige